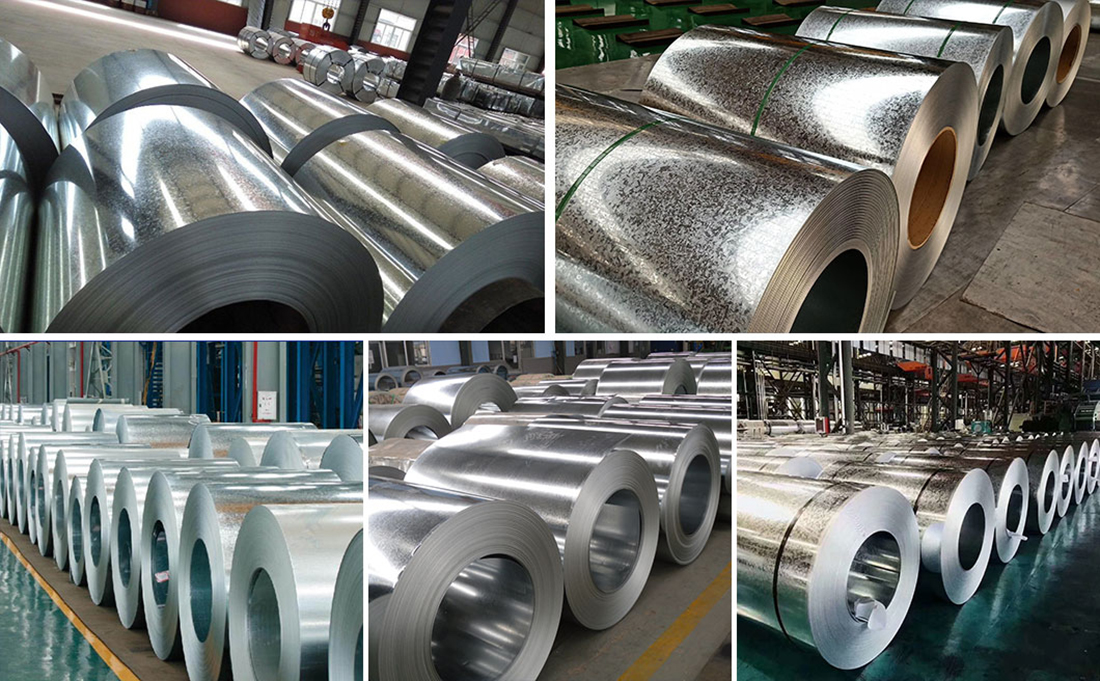

Ikhoyili yentsimbi eyenziwe ngesinyithi iDx51 yaseTshayina Umzi-mveliso wentsimbi eshushu Dipped intsimbi yesinyithi / amaxabiso entsimbi aqengqelekayo / GI Coil

Inkcazo yokucwenga

(1) Ukugquma kwe-spangle eqhelekileyo

Kwinkqubo eqhelekileyo yokuqina yomaleko we-zinc, iinkozo ze-zinc zikhula ngokukhululekileyo ukuze zenze i-coating ene-spangle morphology ecacileyo.

(2) ukunciphisa ukugquma kwe-spangle

Ngexesha lokuqiniswa komgangatho we-zinc, iinkozo zekristale ye-zinc zithintelwe ngokungekho ngqiqweni ukwenza eyona nto incinci yokwambathisa ispangle.

(3) Ukwaleka okungenaspangle-free

Ifunyenwe ngokulungelelanisa ukubunjwa kweekhemikhali zesisombululo se-plating, ayinayo i-morphology ebonakalayo ye-spangle, kwaye inombala ofanayo womphezulu.

(4) I-Zinc-iron alloy coating

Intsimbi yentsimbi emva kokudlula kwindawo yokuhlambela i-galvanizing iphathwa ubushushu ukuze yenze i-alloy layer ye-zinc kunye nentsimbi kulo lonke uphahla. Olu tyaba lunembonakalo emnyama engwevu ngaphandle kokucwebezela kwesinyithi, kwaye kulula ukuba ngumgubo ngexesha lenkqubo yobundlobongela. Ukongeza ekucoceni, isambatho sinokupeyintwa ngokuthe ngqo ngaphandle konyango olongezelelweyo.

(5) ukwahlula ukwahlula

Kumacala omabini ephepha lensimbi, iingubo ezinobunzima obuhlukeneyo be-zinc ziyafuneka.

(6) Ukudlula kolusu olugudileyo

I-Smoothing luhlobo oluthile olubandayo lwe-galvanized sheet sheet kunye ne-deformation encinci ye-deformation enye okanye ezininzi zezi njongo zilandelayo.

Ukuphucula inkangeleko yomgangatho weshiti lentsimbi okanye ulungele ukugquma; nciphisa okwethutyana umgca wokutyibilika (umgca weLüdes) okanye imibimbi eveliswe xa imveliso egqityiweyo isenziwa.

Isiphene

Ngokukodwa zibandakanya: ukuchithwa, imikrwelo, amabala e-passivation, amasuntswana e-zinc, imiphetho engqindilili, imivimbo yemela yomoya, imikrwelo yemela yomoya, intsimbi eveziweyo, ukufakwa, ukonakala komatshini, ukungasebenzi kakuhle kwesiseko sentsimbi, imiphetho yamaza, i-buckling, ukungahambelani kobungakanani, i-Embossing, inconsistent zinc layer, rollprint, njl.

Izizathu eziphambili zokuwa kwe-zinc layer zezi: i-oxidation yomhlaba, iikhompawundi ze-silicon, i-emulsion epholileyo epholileyo epholileyo, i-oxidizing umoya ophezulu kakhulu kunye nendawo yokukhusela igesi yegesi kwicandelo le-NOF, umlinganiselo ongekho ngqiqweni we-air-fuel, ukuhamba kwe-hydrogen ephantsi, ukungena kwe-oksijini kwisithando somlilo, i-strip steel Ubushushu bokungena kwi-furnace ye-WP iphantsi, icandelo le-furnace liphantsi, icandelo le-furnace liphantsi, icandelo le-furnace liphantsi. ukufunxa, ukushisa kwesithando somlilo kwicandelo le-NOF liphantsi, igrisi ayiguquki, umxholo we-aluminium wembiza ye-zinc uphantsi, isantya seyunithi sikhawuleza kakhulu, ukunciphisa akwanelanga, kwaye i-zinc liquid ihlala Ixesha lifutshane kakhulu kwaye isambatho sinzima kakhulu.

Izizathu zomhlwa omhlophe kunye namabala amnyama zimi ngolu hlobo lulandelayo: amabala amnyama akhiwa ngokunyuka kwe-oxidation ye-rust emhlophe.

Oonobangela abaphambili berusi emhlophe ngaba:

(1) Ukungashukumi kakuhle, ukungonelanga okanye ukungalingani kwefilim ye-passivation;

(2) Umphezulu awufakwanga ioli okanye kukho ukufuma okushiyekileyo kumphezulu womgca;

(3) Umphezulu wentsimbi yomtya uqulethe ukufuma ngexesha lokujiya;

(4) I-passivation ayomiswanga ngokupheleleyo;

(5) Ukufuma okanye imvula ngexesha lokuthuthwa okanye ukugcinwa;

(6) Imveliso egqityiweyo igcinwe ixesha elide kakhulu;

(7) Ishiti elifakwe igalvanized lidibene okanye ligcinwe kunye nezinye izinto eziyingozi ezifana neasidi kunye nealkali.

Indawo yokugcina impahla

Le nkampani inemigca emibini yokuvelisa ipleyiti ebanzi ebanzi nengqindilili enobugcisa obuthembekileyo, kwaye inamandla abanzi okuvelisa iitoni ezingaphezulu kwezigidi ezi-5 zentsimbi etyhidiweyo kunye neetoni ezingaphezu kwezigidi ezi-3 zeepleyiti zentsimbi ngonyaka. Inani labasebenzi lifikelela ngaphezu kwe-10,000. Inetekhnoloji yonyango lwentsimbi yentsimbi, itekhnoloji yokuvelisa ipleyiti etyebileyo, itekhnoloji yokuvelisa intsimbi ye-electroslag, njl.

Ukupakisha kunye nokuthunyelwa

Sinokubonelela: ukupakishwa kweplanga yeplanga, ukupakishwa kwebhokisi yeplanga, ukupakishwa kwentsimbi, ukupakishwa kweplastiki kunye nezinye iindlela zokupakisha. Sizimisele ukupakisha kunye nokuhambisa iimveliso ngokobunzima, iinkcukacha, izixhobo, iindleko zoqoqosho kunye neemfuno zabathengi.

Indlela yokuthutha: Sinokubonelela ngezothutho zesikhongozeli okanye isambuku, indlela, umzila kaloliwe okanye umzila wamanzi wangaphakathi kunye nezinye iindlela zothutho zomhlaba ezithunyelwa ngaphandle. Kakade ke, ukuba kukho iimfuno ezikhethekileyo, sinokusebenzisa izithuthi zomoya.

Ingxelo yomthengi

Nceda uzive ukhululekile ukusishiya umyalezo ukuba unombuzo malunga nathi kunye neemveliso zethu.